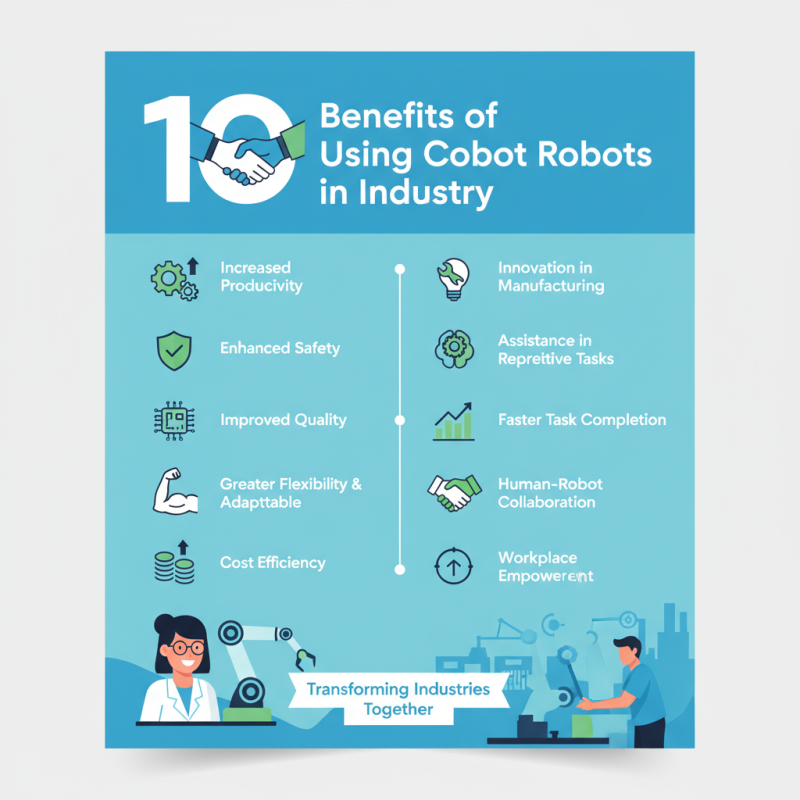

Top 10 Benefits of Using Cobot Robots in Industry?

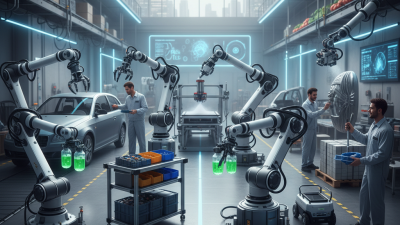

In today's manufacturing landscape, cobot robots play a crucial role in enhancing productivity. Dr. Emily Johnson, a leading expert in robotics, emphasizes, "Cobot robots are transforming how industries operate." Their collaborative nature allows them to work alongside human workers effectively.

Cobot robots are designed to assist in various tasks, from assembly to packaging. Unlike traditional robots, they are safer and more adaptable. Many businesses have reported increased efficiency after integrating cobots. However, challenges remain in ensuring smooth human-robot interactions.

The potential of cobot robots is undeniable. Yet, organizations must consider their implementation carefully. Training and integration strategies are paramount for success. Balancing automation and human skills can lead to innovation. Embracing this technology may require a shift in mindset and practices for many.

Advantages of Enhanced Productivity with Cobot Robots in Industry

Cobot robots significantly boost productivity in industrial settings. Recent studies indicate that integrating cobots can increase production rates by up to 30%. These robots perform repetitive tasks efficiently, allowing human workers to focus on more complex functions. For instance, a manufacturer reported a 20% reduction in assembly times after deploying cobots alongside human operators.

However, some challenges remain. Businesses often struggle with employee training and cobot integration. It's essential to ensure workers are comfortable around these machines. Interaction can cause anxiety for some. Companies must invest in training programs to mitigate this. Another concern is the initial investment cost. Budgeting for cobots can be a hurdle, but many firms find that productivity gains justify the expense.

Cobot technology is evolving rapidly. The flexibility of these robots allows for quick task adaptations, a major advantage in today's fast-paced production environments. Reports show that 70% of organizations plan to increase their use of cobots within the next five years. Embracing this trend can lead to a more productive and efficient workforce. However, companies need to continuously evaluate their strategies for optimal results.

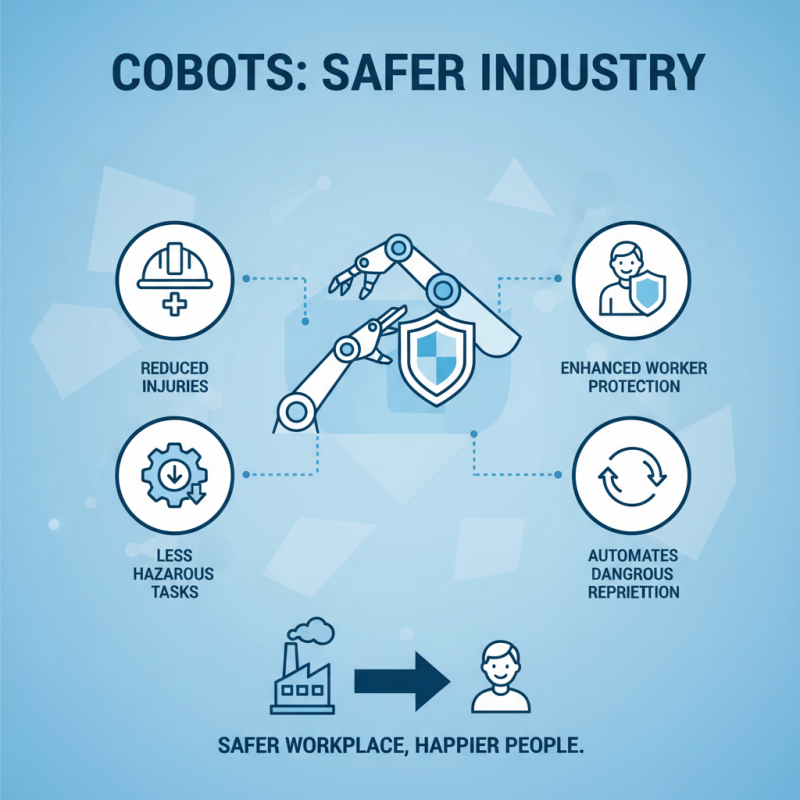

Improved Safety and Reduced Risk of Injury through Cobot Integration

Cobot robots are changing the game in industrial settings. One of their greatest advantages is improved safety. These robots work alongside humans, reducing the likelihood of workplace injuries. They can handle repetitive and dangerous tasks that carry a higher risk. As a result, workers are less exposed to hazardous situations.

Integration of cobots often leads to a more ergonomic work environment. By taking on heavy lifting and precise maneuvers, cobots decrease physical strain on employees. This shift can improve morale and productivity as workers focus on more skilled tasks. The reality is, however, that safety measures must still be maintained. Robots do make errors, and human oversight is crucial.

Tips for implementing cobots safely include training staff on protocols. Proper communication between humans and machines is essential. Regular maintenance checks can prevent malfunctions. Moreover, evaluating the workflow before adopting cobots can highlight potential risks and benefits. Seeing where cobots fit in can lead to smarter resource allocation.

Flexibility and Adaptability of Cobots for Varied Industrial Applications

Cobot robots are transforming industries with their unique flexibility and adaptability. Unlike traditional robots, cobots can work alongside human operators. This collaboration makes them ideal for varied industrial applications, from assembly lines to packaging. They can easily switch tasks based on production needs, enhancing efficiency.

Tips: Assess your workspace. Ensure there's enough room for cobots and humans to work side by side. This synergy promotes safety and productivity. Consider integrating cobots into repetitive or tedious tasks. Employees can then focus on more strategic roles, leading to better job satisfaction.

Cobot technology allows for quick reprogramming. This feature supports diverse tasks. However, training is vital. Workers need guidance to interact safely with these machines. Regular feedback can improve the partnership between humans and cobots. It's essential to reflect on areas for improvement and adapt accordingly. Continuous learning is crucial in this evolving landscape.

Ease of Collaboration between Humans and Cobots in Work Environments

Collaborating with cobot robots in the workplace is transforming industries. Unlike traditional robots, cobots work alongside humans, enhancing productivity. A recent industry report revealed that companies using cobots saw productivity increases of 40%. This vast improvement is a game-changer for manufacturing and logistics.

Ease of collaboration is essential. Cobots are designed to be user-friendly. Employees can quickly adapt to their operation without extensive training. They can assist in heavy lifting or repetitive tasks, allowing workers to focus on more complex functions. However, integrating cobots can sometimes lead to initial resistance. Workers may fear job displacement or struggle to trust their robotic partners. Engaging employees in training can mitigate these concerns, fostering a smoother transition.

Tip: Encourage open communication with your team. Discuss how cobots can complement their roles instead of replacing them. Understanding the true capabilities of these machines can foster a culture of cooperation.

Another consideration is safety. Although cobots are designed with safety features, accidents can happen. Regular maintenance checks and employee training on safe interaction with cobots are crucial. Balancing efficiency and safety is a continuous challenge that companies must address.

+91-97254 16844

+91-97254 16844