10 Best Benefits of Cobot Automation for Modern Manufacturing

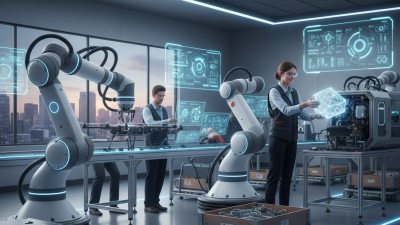

In the realm of modern manufacturing, the integration of cobot automation has ushered in a transformative era characterized by increased efficiency and enhanced operational capabilities. As companies continue to seek competitive advantages in a rapidly evolving industry, cobots, or collaborative robots, have emerged as vital assets. Dr. Sarah Thompson, a leading expert in robotic automation, emphasizes this shift, stating, “Cobot automation not only streamlines production processes but also enhances the synergy between human workers and machines.”

The benefits of cobot automation extend far beyond mere productivity gains. These advanced systems are designed to work alongside human operators, fostering a collaborative environment that improves safety and minimizes the physical strain on workers. Additionally, the flexibility of cobots allows for seamless adaptation to various tasks, making them an invaluable asset in manufacturing environments that demand quick changes and responsiveness to market dynamics.

As industries embrace the transformative potential of cobot automation, understanding its implications becomes imperative. The ten best benefits of implementing cobot solutions pave the way for a future where manufacturing is not only more efficient but also more sustainable, ultimately reshaping the landscape of production in the years to come.

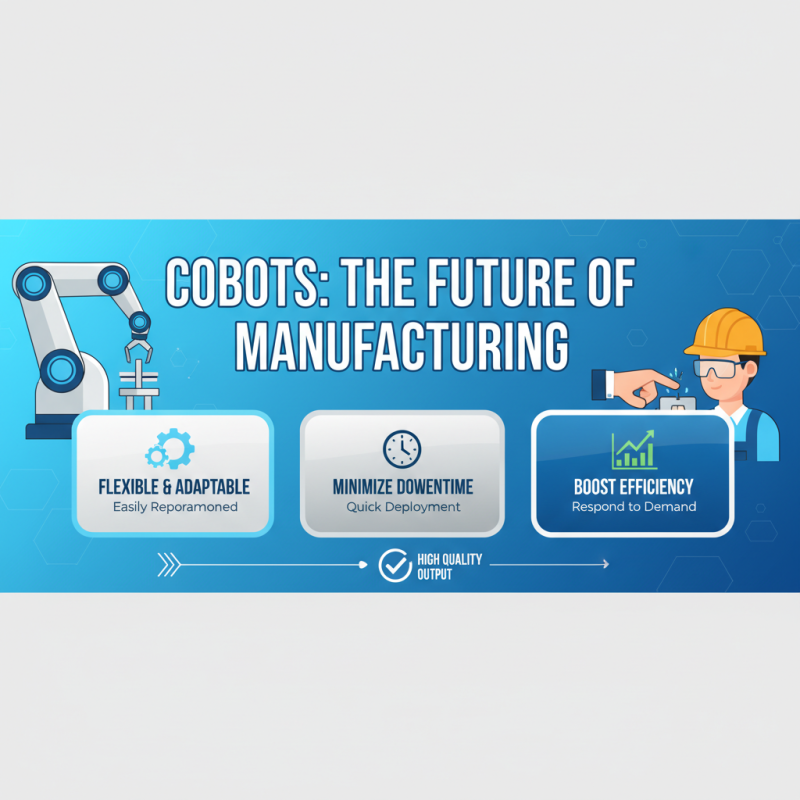

The Rise of Cobots in Modern Manufacturing

The rise of collaborative robots, or cobots, in modern manufacturing marks a significant shift in how industries approach production efficiency and workforce collaboration. Unlike traditional industrial robots, cobots are designed to work alongside human operators, enhancing productivity while ensuring safety. This harmonious interaction not only streamlines operations but also empowers workers by allowing them to focus on more complex and fulfilling tasks, rather than repetitive manual labor.

As cobots become increasingly integrated into manufacturing processes, their ability to improve flexibility and responsiveness has profound implications for the industry. They can be easily reprogrammed for different tasks, enabling manufacturers to adapt more readily to changing demands or new product lines. This adaptability is especially valuable in today’s fast-paced market where agility is key. Moreover, the user-friendly design of cobots often requires minimal training, making it easier for companies to implement these advanced solutions without significant disruptions to their existing workflows. This shift signifies a crucial step towards a more efficient and innovative manufacturing landscape, where human creativity and robotic precision work together seamlessly.

Enhancing Efficiency through Cobot Automation

Cobot automation is revolutionizing modern manufacturing by significantly enhancing efficiency across various processes.

Collaborative robots, or cobots, are designed to work alongside human operators, complementing their skills and boosting productivity.

According to a recent report by the International Federation of Robotics, companies that integrate cobots into their operations can see productivity improvements of

up to 30%, as these machines can handle repetitive tasks with precision and speed, allowing human workers to focus on

more complex and value-added activities.

One of the key benefits of cobot automation is its ability to adapt to different tasks and environments.

As stated in a study by McKinsey & Company, around 60% of occupations could be partially automated, suggesting that cobots can

be deployed in a variety of roles, enhancing flexibility in manufacturing lines.

Moreover, the integration time for cobots is relatively short, often requiring minimal programming due to their intuitive design.

This ensures a rapid return on investment and a smoother transition for teams moving towards automation.

Tip: When considering the implementation of cobots, involve your workforce in the planning stages.

Their insights can help identify the most beneficial applications and ensure a more seamless integration into existing processes.

Another advantage of cobot automation is the increase in workplace safety.

A report by OSHA indicates that automation can lead to a 50% reduction in workplace injuries.

Cobots are equipped with advanced sensors and safety features that allow them to detect human presence and respond accordingly,

minimizing the risk of accidents. This not only creates a safer working environment but also reduces downtime,

further enhancing overall operational efficiency.

Tip: Regularly review and update safety protocols to incorporate the latest cobot capabilities,

ensuring that all employees understand how to work safely alongside these advanced tools.

Improving Workplace Safety with Collaborative Robots

Collaborative robots, or cobots, have rapidly become an integral part of modern manufacturing, particularly in enhancing workplace safety. According to a recent report by the International Federation of Robotics, the implementation of cobots has led to a significant reduction in workplace injuries, contributing to a safer working environment. These robots are designed to work alongside human operators, taking over dangerous or repetitive tasks while allowing workers to focus on more complex activities. This collaborative approach not only increases productivity but also mitigates the risks associated with heavy lifting and hazardous operations.

Tips for integrating cobots into your manufacturing process include conducting a thorough risk assessment to identify potential hazards and determining which tasks can be safely automated. It's essential to provide comprehensive training for employees interacting with these robots, ensuring they understand the safety protocols and emergency procedures. Moreover, regular maintenance of cobots is vital to minimize risks and ensure they operate efficiently without posing a danger to human operators. By fostering a culture of collaboration and safety, businesses can maximize the benefits of cobot automation, ultimately leading to improved well-being for their workforce.

Implementing cobots can also lead to better ergonomics in the workplace. The World Health Organization has highlighted that poor ergonomics is a leading cause of workplace injuries. By enabling robots to perform strenuous tasks, human workers can avoid repetitive strain injuries, enhancing their overall job satisfaction and productivity. Sharing knowledge regarding the appropriate and safe use of cobots can further reinforce safety measures and inspire confidence among workers, fostering a harmonious and secure manufacturing environment.

Cost-Effectiveness of Cobots in Production Lines

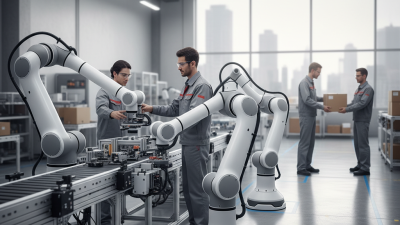

In today's competitive manufacturing landscape, cost-effectiveness is a crucial factor driving the adoption of collaborative robots, or cobots, on production lines. Cobots are designed to work alongside human operators, enhancing efficiency while reducing operational costs. One of the primary financial advantages they offer is their ability to perform repetitive tasks with precision, minimizing errors and waste. This leads to significant savings in raw materials and labor costs, as businesses can streamline their processes and allocate human workers to more complex tasks that require critical thinking and creativity.

Moreover, the initial investment in cobot technology is often offset by the long-term savings and increased productivity they deliver. Unlike traditional industrial robots, which usually require extensive safety measures, cobots are inherently safer and more user-friendly, allowing manufacturers to deploy them without costly safety cages and equipment modifications. This lowers the barriers to automation for small and medium-sized enterprises, enabling these businesses to capitalize on automation without overwhelming initial expenses. As a result, cobots not only enhance productivity but also contribute to a more sustainable approach to manufacturing, where reduced operational costs and increased flexibility can lead to a more robust economic performance.

Flexibility and Adaptability of Cobots in Various Industries

Cobots, or collaborative robots, are rapidly transforming the landscape of modern manufacturing due to their unique flexibility and adaptability. Unlike traditional industrial robots, which are typically designed for specific tasks in rigid environments, cobots can easily be reprogrammed and deployed across various applications within the same facility. This capability enables manufacturers to respond quickly to changing production demands, whether it's adapting to new product lines or scaling operations during peak times. As a result, businesses can minimize downtime and maximize efficiency, all while maintaining high standards of quality.

Moreover, the ability of cobots to work alongside human operators enhances productivity in ways previously thought impossible. Their built-in sensors and advanced algorithms allow them to learn from human movements and adapt to different workflows seamlessly. This collaborative nature fosters an environment where human workers can focus on more complex and creative tasks while leaving repetitive and physically demanding jobs to cobots. This synergy not only improves overall operational flexibility but also contributes to a safer workplace, as cobots can take on hazardous tasks, relieving human workers from potential injury. As industries continue to evolve, the adaptability of cobots will be key to meeting diverse manufacturing challenges across sectors.

+91-97254 16844

+91-97254 16844