o

p

t

i

m

a

r

o

b

o

t

i

c

s

Blogs

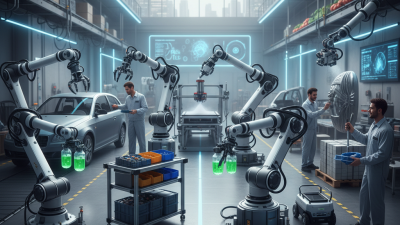

Let us know and we will automate, together to fit your industrial needs.

Do you need Help? Get in touch.

X

Please fill out the form below and we will get back to you as soon as possible.

+91-97254 16844

+91-97254 16844