How to Choose the Right Collaborative Robots for Your Business Needs

In today's rapidly evolving industrial landscape, businesses are increasingly turning to technology to enhance operational efficiency and improve productivity. One of the most promising developments in this domain is the emergence of collaborative robots, commonly referred to as cobots. These robots are designed to work alongside human operators, providing the flexibility and adaptability needed in a dynamic work environment. However, the wide variety of options available can make selecting the right collaborative robots for your specific business needs a daunting task.

When considering the adoption of collaborative robots, it is crucial for businesses to evaluate their unique operational requirements, workforce dynamics, and production goals. Understanding the capabilities of cobots, such as their ease of programming, safety features, and integration with existing systems, can greatly influence the decision-making process. Moreover, organizations must assess the specific tasks these robots will perform and how they can complement human labor, ultimately enhancing productivity without compromising safety or job satisfaction.

By carefully analyzing these factors and matching them to the appropriate collaborative robots, companies can make informed choices that align with their strategic objectives. This introduction aims to guide businesses through the essential considerations involved in selecting the right cobots, ensuring that investments are not only beneficial but also drive long-term growth and innovation.

Understanding Collaborative Robots: Definition and Benefits

Collaborative robots, or cobots, are designed to work alongside humans in a shared workspace, enhancing productivity and safety in various industries. Unlike traditional industrial robots, which often require safety cages and strict operational boundaries, cobots are equipped with advanced sensors and software that allow them to interact safely with human workers. According to a report by Research and Markets, the global collaborative robot market size was valued at approximately $710 million in 2020 and is projected to reach over $12 billion by 2027, indicating a significant trend towards automation that complements the human workforce.

The benefits of integrating collaborative robots into business operations are manifold. They are highly versatile and can perform a range of tasks, from assembly and packaging to welding and quality control. This flexibility allows businesses to scale operations quickly without the need for extensive reconfiguration. A study by McKinsey & Company found that 60% of all occupations could see at least 30% of their activities automated, suggesting that cobots can play a crucial role in enhancing efficiency while freeing human workers to focus on more complex tasks that require critical thinking and problem-solving skills. Additionally, the adoption of cobots can lead to a reduction in operational costs and an increase in throughput, making them an attractive option for industries aiming to remain competitive in today's fast-paced market.

Collaborative Robots Benefits vs. Challenges

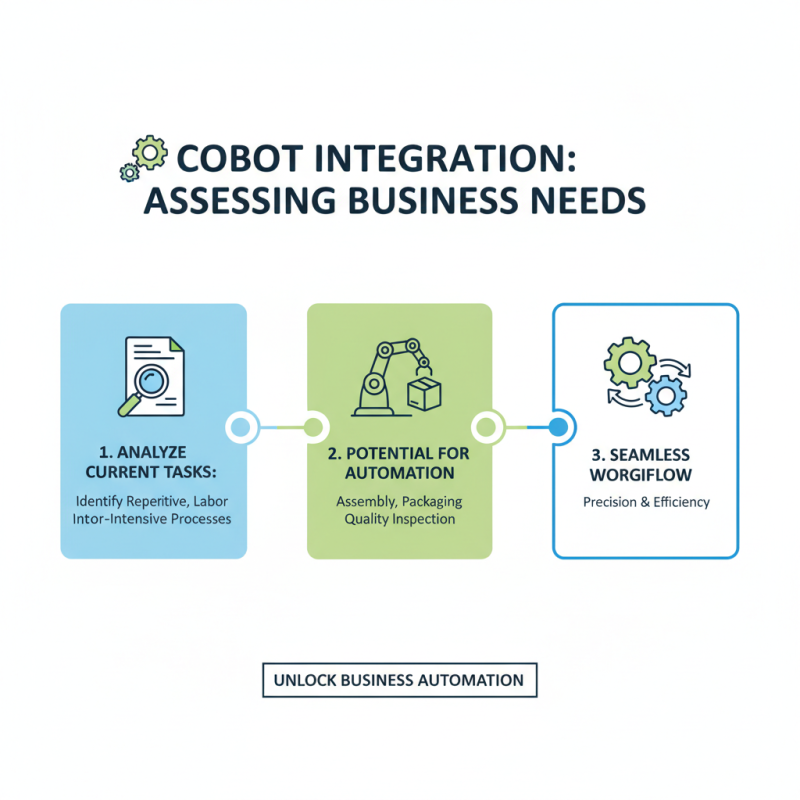

Assessing Business Needs: Analyzing Tasks and Processes for Automation

When considering the integration of collaborative robots into your business, it's crucial to assess your specific business needs carefully. Start by analyzing the tasks currently performed within your operations. Identify repetitive or labor-intensive processes that could benefit from automation. This could include tasks such as assembly, packaging, or quality inspection, where precision and efficiency are paramount. By documenting these tasks, you can evaluate their potential for improvement through automation, ensuring that the collaborative robots you choose can seamlessly integrate into your existing workflow.

Next, consider the processes associated with the identified tasks. Analyzing these processes involves understanding the sequence, timing, and required resources. Look for bottlenecks or inefficiencies that collaborative robots could help eliminate. Assess the safety and ergonomic aspects of the current operations, as collaborative robots can enhance workplace safety by taking over hazardous tasks. Additionally, evaluate the skill levels of your workforce; robots can supplement human efforts, allowing your team to focus on more complex and nuanced activities. Through this comprehensive analysis, you can confidently select collaborative robots that align with your business goals, ensuring a smooth transition to automation.

Evaluating the Different Types of Collaborative Robots Available

When evaluating the different types of collaborative robots (cobots) available for business needs, it’s essential to consider their various functionalities and applications. According to a report by MarketsandMarkets, the global cobot market is projected to reach USD 12.3 billion by 2025, growing at a CAGR of 34.5%. This rapid growth is indicative of the diverse technology and capabilities that cobots offer, making them suitable for a range of industries, from manufacturing to healthcare.

Cobots can be categorized primarily into three types: light-weight industrial cobots, mobile cobots, and service cobots. Lightweight industrial cobots are designed for tasks like assembly, packing, and palletizing, often working alongside human operators without safety cages. This type is crucial in small to medium-sized manufacturing environments where flexibility and safety are paramount. Mobile cobots, on the other hand, are equipped with navigation technologies that enable them to transport materials and assist in logistics. This is particularly beneficial in large facilities like warehouses, where efficiency in material handling can significantly enhance productivity. Lastly, service cobots assist in performing specific tasks in sectors like healthcare and hospitality, assisting staff with repetitive or labor-intensive jobs.

When selecting a cobot, businesses should assess their specific needs—such as load capacity, reach, and integration capabilities—with the goal of optimizing processes while ensuring worker safety and productivity. Furthermore, adopting the right cobot aligns with the Industry 4.0 trend, as research from McKinsey identifies that automation technologies, including cobots, could add up to $4.5 trillion in economic value by 2025. Thus, understanding the diversity of cobots is essential for businesses to enhance their operational efficiencies and innovate their work environments.

Key Features to Consider When Choosing a Collaborative Robot

When selecting a collaborative robot (cobot) for your business needs, several key features should be considered to ensure optimal performance and compatibility with your operational requirements. Firstly, payload capacity is crucial; this indicates how much weight the robot can handle, which directly impacts its application scope. Businesses should assess their specific tasks—whether they involve light assembly, heavy lifting, or delicate handling—and choose a cobot that can effectively manage these demands without compromising safety or efficiency.

Another significant feature is the robot's safety mechanisms. Collaborative robots are designed to work alongside humans, so built-in safety features such as force sensors, emergency stops, and compliant movements are essential. These ensure that the robot can operate in shared spaces without posing risks to human workers. Additionally, ease of programming and integration into existing workflows plays a pivotal role; look for cobots that offer intuitive programming interfaces and compatibility with your current systems. This will not only reduce downtime during installation but also facilitate quick adaptations as business needs evolve.

Integration and Support: Ensuring Compatibility with Existing Systems

When choosing collaborative robots (cobots) for your business, ensuring their compatibility with existing systems is crucial for seamless integration. Businesses often rely on a variety of machinery and software to maintain productivity. Therefore, before incorporating new cobots, it’s essential to assess how they will interact with current equipment and workflows. Analyzing the communication protocols, data exchange formats, and physical interfaces of both the cobots and existing systems can help identify potential challenges early in the implementation process.

Moreover, robust support and training are vital for ensuring successful integration. Organizations should focus on providers that offer extensive documentation, user-friendly interfaces, and responsive customer service. Investing time in training staff will empower them to operate the cobots effectively and troubleshoot any issues that arise. Additionally, ongoing technical support can facilitate adjustments as production demands evolve, ensuring that the collaborative robots continue to provide value in a dynamic work environment. By prioritizing integration and support, businesses can maximize the return on investment for their cobot initiatives.

How to Choose the Right Collaborative Robots for Your Business Needs - Integration and Support: Ensuring Compatibility with Existing Systems

| Dimension |

Details |

| Robot Type |

Collaborative |

| Payload Capacity |

5 kg - 25 kg |

| Reach |

600 mm - 1,700 mm |

| Integration Ease |

Plug-and-play with existing systems |

| Software Compatibility |

Supports major operating systems and software interfaces |

| Safety Features |

Force limitation, sensors for environment awareness |

| Support and Resources |

24/7 customer support and comprehensive documentation |

| Training Availability |

Online tutorials and on-site training options |

| Cost Range |

$5,000 - $50,000 |

+91-97254 16844

+91-97254 16844