How to Choose the Right Cobot for Your Universal Robot Applications

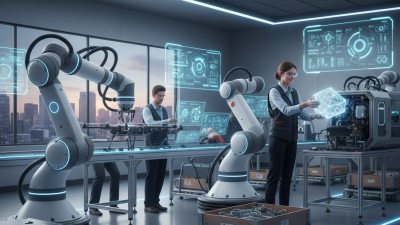

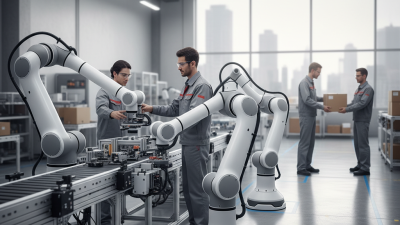

In recent years, the integration of collaborative robots, or cobots, into various industries has transformed the way tasks are performed, enabling enhanced efficiency and safety in the workplace. Specifically focusing on cobot universal robots, these versatile automated solutions are designed to work alongside humans, making them ideal for a range of applications from manufacturing to logistics. However, selecting the right cobot for your specific needs can be challenging given the diverse range of options available.

Understanding the key features and capabilities of cobot universal robots is crucial in making an informed decision. Factors such as payload capacity, reach, ease of programming, and safety features play a significant role in ensuring that the chosen cobot not only fits within the operational parameters but also complements the existing workforce effectively. By carefully assessing the unique requirements of your application and the operational environment, you can identify the best cobot solution that will ultimately enhance productivity and collaboration in your workplace.

Factors to Consider When Selecting a Cobot for Universal Robot Applications

When selecting a collaborative robot (cobot) for universal robot applications, various factors must be carefully considered to ensure optimal performance and integration into existing workflows. First and foremost, the payload capacity of the cobot should align with the demands of the specific task. According to industry reports, cobots typically have payload capacities ranging from 3 kg to 16 kg, making it essential to assess the weight of the materials or components that will be handled. Underestimating the required payload capacity can lead to inefficiencies or the inability to perform tasks altogether.

Moreover, the environment in which the cobot will operate plays a crucial role in the selection process. Factors such as the presence of dust, moisture, and extreme temperatures can influence a cobot's performance and durability. For instance, a report by the International Federation of Robotics indicates that 24% of cobot applications are deployed in manufacturing environments requiring robust protection from various pollutants. Therefore, opting for a cobot with suitable ingress protection ratings can significantly enhance operational longevity and reliability.

Lastly, the ease of programming and integration capabilities should not be overlooked. Research indicates that user-friendly interfaces and simplified programming can reduce setup times by up to 30%, allowing businesses to achieve faster return on investment. As the demand for adaptive automation grows, selecting a cobot that offers flexible programming options and seamless connectivity with existing software platforms becomes increasingly important to cater to evolving operational needs.

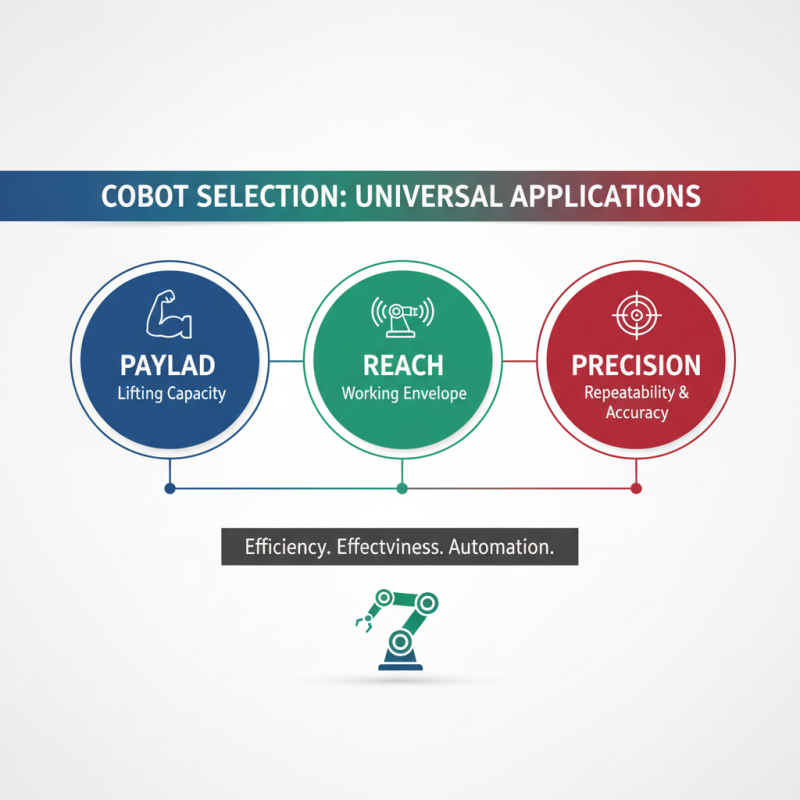

Key Specifications of Cobots: Payload, Reach, and Precision Requirements

When selecting a collaborative robot (cobot) for universal applications, three key specifications stand out: payload, reach, and precision. Understanding these parameters is crucial, as they directly impact the efficiency and effectiveness of your automation processes.

Payload capacity refers to the maximum weight a cobot can handle, which is essential for determining its suitability for various tasks. If your application involves heavy lifting or manipulation of substantial objects, opting for a cobot with a higher payload rating will ensure durability and performance. Conversely, for lighter tasks, a cobot with lower payload capacity may suffice, potentially reducing costs and energy consumption.

Reach is another vital specification that dictates the working envelope of the cobot. It’s important to choose a model that can comfortably cover the distance needed to perform tasks within your application space. An adequate reach not only enhances productivity but also minimizes unnecessary movements that can lead to wear and tear on the robot. Lastly, precision is critical in applications that require meticulous handling, such as assembly or packaging. Cobots with high precision ratings can ensure consistent quality and reduce errors, making them ideal for tasks where exactitude is paramount. By carefully evaluating these specifications, businesses can make informed decisions that optimize performance and return on investment.

Assessing Safety Features in Cobots for Human-Centric Work Environments

When selecting a collaborative robot (cobot) for applications in human-centric work environments, assessing safety features is paramount. Cobots are designed to work alongside human operators, making it essential to ensure their safety to prevent workplace injuries. Look for safety features such as force and torque sensing capabilities, which allow the cobot to detect when it has come into contact with a person or an object, enabling it to react appropriately by stopping or slowing down. These features are especially crucial in environments where operators and robots share space, minimizing the risks of accidents.

In addition to sensing capabilities, consider the built-in safety standards that govern the design and functionality of the cobot. Many cobots come with integrated safety software that monitors operational conditions in real-time and can halt operations if any unsafe behavior is detected. Moreover, it's important to evaluate whether the cobot supports safety-certified operating modes, such as reduced speed or power modes, during collaborative tasks. This adaptability allows for seamless integration into workflows where human presence is constant, thus enhancing operational efficiency while maintaining a high standard of safety. Choosing a cobot with robust safety features ensures not only compliance with industry regulations but also promotes a culture of safety within the workplace.

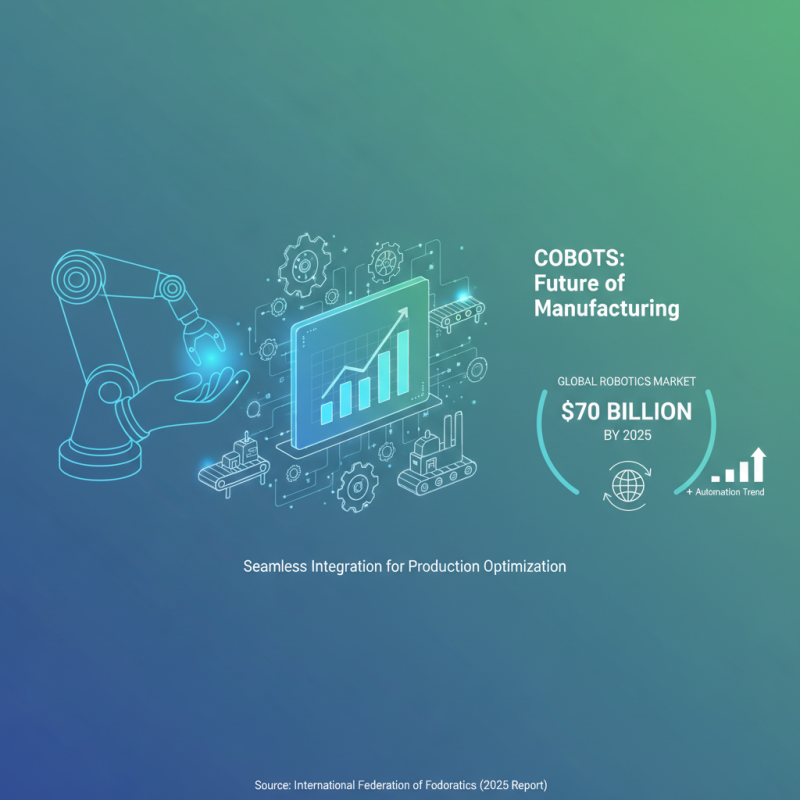

Understanding Integration Capabilities of Cobots with Existing Production Systems

In today’s manufacturing landscape, understanding the integration capabilities of collaborative robots (cobots) is crucial for optimizing production systems. According to a report by the International Federation of Robotics, the global market for industrial robots, including cobots, is expected to reach approximately $70 billion by 2025, reflecting a growing trend toward automation in manufacturing. Organizations are increasingly seeking robots that can seamlessly interact with their existing machinery and workflows to enhance productivity while minimizing disruption.

Effective integration requires cobots that are designed with interoperability in mind, which includes compatibility with various programming languages and communication protocols used within production environments. Research conducted by the Association for Advancing Automation indicates that about 69% of manufacturers recognize the importance of having robots that can work alongside legacy equipment. This is particularly significant because many production lines still rely on older machinery; therefore, cobots must be able to efficiently communicate and adapt to these systems for enhanced operational efficiency.

Furthermore, the ease of integration can substantially reduce the time and cost associated with implementation. Industry data suggests that organizations that invest in adaptable cobots experience a reduction in deployment times by as much as 30%, allowing for quicker returns on investment. By prioritizing the integration capabilities of cobots, manufacturers can ensure a smoother transition to automation while maximizing the effectiveness of their current production systems.

Cost-Benefit Analysis: Evaluating ROI of Cobots in Universal Robot Applications

Evaluating the return on investment (ROI) of collaborative robots (cobots) in universal robot applications is pivotal for businesses aiming to enhance their automation efforts while maintaining cost-effectiveness. A recent study by the Association for Advancing Automation highlights that manufacturers leveraging cobots can achieve up to a 40% increase in productivity and a reduction in operational costs by as much as 30%. These figures underscore the potential financial benefits of integrating cobots into production lines, making it essential for companies to conduct a thorough cost-benefit analysis.

When evaluating the ROI, organizations should consider both direct and indirect benefits of cobot implementation. Direct benefits include lower labor costs and reduced cycle times, while indirect benefits encompass improved product quality and employee satisfaction by allowing workers to focus on higher-value tasks. According to a report from the International Federation of Robotics, businesses that implemented cobots reported a notable 20-25% increase in employee engagement, as workers are relieved from monotonous tasks. By quantifying these advantages against the initial investment cost of cobots, companies can make informed decisions that align with their operational goals, ultimately driving growth and profitability in their universal robot applications.

How to Choose the Right Cobot for Your Universal Robot Applications - Cost-Benefit Analysis: Evaluating ROI of Cobots in Universal Robot Applications

| Cobot Model |

Purchase Cost ($) |

Annual Operating Cost ($) |

Labor Savings ($/year) |

ROI (%) |

Payback Period (months) |

| Cobot A |

15,000 |

3,000 |

10,000 |

46.67% |

18 |

| Cobot B |

20,000 |

4,000 |

15,000 |

55.56% |

16 |

| Cobot C |

12,000 |

2,500 |

8,000 |

56.25% |

15 |

| Cobot D |

18,500 |

3,800 |

12,000 |

38.46% |

21 |

+91-97254 16844

+91-97254 16844