Top Advantages of Cobot Automation in 2025 for Smart Manufacturing

In the rapidly evolving landscape of smart manufacturing, cobot automation emerges as a transformative force, paving the way for streamlined processes and enhanced productivity. According to Dr. Sarah Thompson, a leading expert in collaborative robotics, "Cobot automation is not just a trend; it's a paradigm shift that empowers manufacturers to optimize their operations while fostering a synergistic relationship between humans and machines." As we approach 2025, the advantages of integrating cobots into manufacturing environments become increasingly pronounced.

The year 2025 is set to witness significant advancements in cobot technology, enabling greater flexibility in production lines and reducing operational costs. This shift is essential for manufacturers aiming to remain competitive in an era characterized by rapid technological changes and evolving consumer demands. With cobot automation, companies can achieve higher precision and efficiency, while also addressing labor shortages by augmenting human capabilities rather than replacing them.

As we delve deeper into the top advantages of cobot automation for smart manufacturing, it becomes clear that embracing this innovative technology is crucial for companies looking to thrive in a future defined by collaboration and intelligent automation. The potential benefits span improved safety, increased productivity, and enhanced workplace satisfaction, making a compelling case for the widespread adoption of cobots in manufacturing settings.

The Definition and Functionality of Cobots in Smart Manufacturing

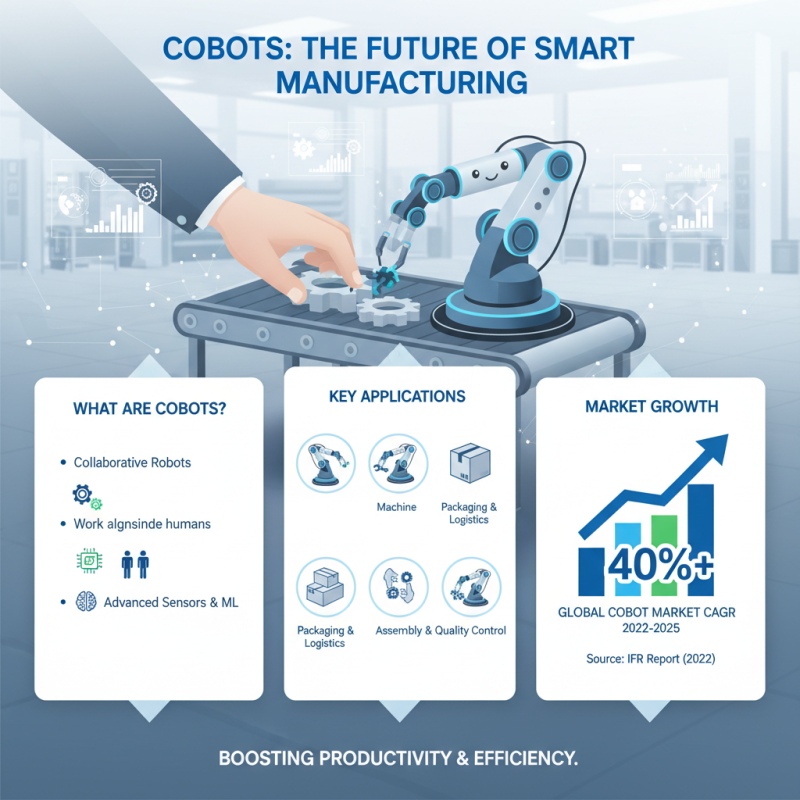

Collaborative robots, or cobots, are set to revolutionize smart manufacturing by enhancing productivity and operational efficiency. Defined as robotic systems designed to work alongside human workers, cobots are equipped with advanced sensors and machine learning capabilities, allowing them to perform tasks such as assembly, packing, and machine maintenance. According to a recent report by the International Federation of Robotics, the global cobot market is expected to grow at a compound annual growth rate (CAGR) of over 40% between 2022 and 2025, reflecting the increasing adoption of automation in manufacturing settings.

Functionally, cobots are designed to be safe and intuitive for human interaction, often requiring minimal programming. This user-friendly nature allows for quick deployment and easy integration into existing workflows, significantly reducing downtime during transitions. A study from McKinsey & Company shows that incorporating cobots can result in a 20-30% increase in production rates while also improving workplace safety by taking over hazardous tasks. These functionalities position cobots as a vital component in the quest for smarter manufacturing processes, making factories more flexible and responsive to changing demands.

Key Advantages of Cobots over Traditional Automation Systems

Cobots, or collaborative robots, represent a significant evolution in automation technology, especially when compared to traditional automation systems. One of the primary advantages of cobots is their ability to work alongside human operators, enhancing productivity without the need for extensive safety measures or physical barriers. This collaborative approach allows for more flexible manufacturing processes, as cobots can be easily integrated into existing workflows and reprogrammed for different tasks as production demands change.

Another key benefit is the ease of use associated with cobots. Unlike traditional robotic systems that often require specialized training and technical knowledge to operate, cobots are designed with user-friendly interfaces and intuitive programming systems. This accessibility empowers operators to program and manage cobots without extensive engineering backgrounds, thereby reducing downtime and enabling quicker adaptation to changing production needs. Additionally, cobots can take on repetitive and mundane tasks, allowing human workers to focus on higher-value activities, thus improving overall operational efficiency and job satisfaction.

Advantages of Cobot Automation in 2025

This chart illustrates the top advantages of collaborative robots (cobots) over traditional automation systems in smart manufacturing for the year 2025. The advantages highlighted include flexibility, cost efficiency, safety, scalability, and ease of use, showcasing the increasing importance of cobots in modern manufacturing processes.

Impact of Cobots on Workforce Dynamics and Employment Trends

The introduction of collaborative robots, or cobots, in smart manufacturing by 2025 is poised to significantly reshape workforce dynamics and employment trends. According to a recent report by the International Federation of Robotics (IFR), the global cobot market is expected to reach $13 billion by 2025, indicating a rapid adoption rate across various sectors. This transition towards automation, facilitated by cobots, is not merely about replacing human labor; instead, it is about enhancing human capabilities. Cobots work alongside human operators, relieving them of repetitive and physically demanding tasks while allowing them to focus on more complex and strategic roles.

The adoption of cobots has led to a paradigm shift in workforce composition. Research from the McKinsey Global Institute suggests that while automation may displace some jobs, it will also create new employment opportunities, particularly in high-skill areas such as robotics management and programming. This shift serves to upskill the workforce, where employees are encouraged to engage in continuous learning to adapt to new technologies.

The flexibility and efficiency offered by cobots drive productivity, leading to a growing demand for skilled workers who can leverage these tools effectively. By 2025, it is anticipated that nearly 60% of workers in manufacturing will be involved with some form of collaborative technology, reshaping the skill sets needed in the industry.

Integration of Cobots with IoT and AI for Enhanced Efficiency

The integration of collaborative robots (cobots) with the

Internet of Things (IoT) and artificial intelligence (AI) is set to revolutionize

smart manufacturing in 2025. By leveraging real-time data and intelligent

analytics, cobots can significantly enhance operational efficiency. This synergy enables a

seamless flow of information between machines and systems, allowing for

predictive maintenance, optimized workflows, and immediate reactions to any anomalies in production processes.

As a result, manufacturers can reduce downtime and increase output quality.

Tips for implementing cobot automation effectively include starting with

pilot projects to gauge performance and scalability. Companies should also ensure that

their IoT infrastructure is robust enough to handle increased data traffic and connectivity demands. Additionally,

upskilling the workforce to understand and interact with these advanced systems will foster a

collaborative environment that maximizes the potential of cobots alongside human workers.

Tips for implementing cobot automation effectively include starting with

pilot projects to gauge performance and scalability. Companies should also ensure that

their IoT infrastructure is robust enough to handle increased data traffic and connectivity demands. Additionally,

upskilling the workforce to understand and interact with these advanced systems will foster a

collaborative environment that maximizes the potential of cobots alongside human workers.

Furthermore, the use of AI algorithms can provide powerful insights into

manufacturing operations. By analyzing patterns and trends, AI can suggest adjustments to workflows, ultimately enhancing productivity.

For successful integration, it is vital to foster a culture of innovation,

encouraging teams to adapt and optimize the use of these technologies consistently. Embracing this change not only drives efficiency

but also positions companies at the forefront of the evolving manufacturing landscape.

Future Trends and Developments in Cobot Technology for 2025

As we look towards 2025, the evolution of collaborative robots, known as cobots, is set to revolutionize smart manufacturing. Key trends indicate that advancements in artificial intelligence and machine learning will enable cobots to become even more intuitive in their operations. These developments will allow them to learn from their environment and adapt to changes in real-time, enhancing their efficiency and versatility on the production floor. Factories will increasingly leverage these capabilities to optimize workflow, reduce downtime, and improve overall productivity.

Moreover, the integration of Internet of Things (IoT) technology with cobots is a significant trend to watch in 2025. This synergy will enable cobots to communicate seamlessly with other machines and systems, facilitating better coordination and management of manufacturing processes. Real-time data analytics will empower manufacturers to make more informed decisions, enhancing predictive maintenance and reducing operational costs. As cobots become smarter and more interconnected, they will play a crucial role in enabling manufacturers to achieve higher levels of automation while maintaining the flexibility needed to respond to dynamic market demands.

Tips for implementing cobot automation effectively include starting with

Tips for implementing cobot automation effectively include starting with

+91-97254 16844

+91-97254 16844