Top 10 Cobot Robot Arm Applications Revolutionizing Industries

As industries continue to evolve towards automation, the adoption of collaborative robots, commonly known as cobots, has gained significant traction. According to a report by the International Federation of Robotics, the global market for cobot robot arms is expected to reach $12.3 billion by 2025, showcasing a compound annual growth rate (CAGR) of 32%. This remarkable growth can be attributed to their ability to work safely alongside human workers, enhancing productivity and efficiency in various sectors, from manufacturing to healthcare.

Cobot robot arms are redefining traditional workflows by performing repetitive and strenuous tasks, allowing human employees to focus on more complex and creative responsibilities. Research by ABI Research highlights that these flexible robotic systems can reduce production costs by up to 25% while improving operational speed by 50%. As industries seek to optimize their processes amid a competitive landscape, the integration of cobot technology is proving to be a game-changer, driving innovation and reshaping the future of work.

In this article, we will explore the top ten applications of cobot robot arms that are revolutionizing industries. From handling hazardous materials in pharmaceuticals to enhancing assembly line efficiencies in automotive manufacturing, these intelligent machines are not only boosting operational capabilities but also paving the way for a new era of human-robot collaboration.

Overview of Cobot Robot Arms and Their Industrial Impact

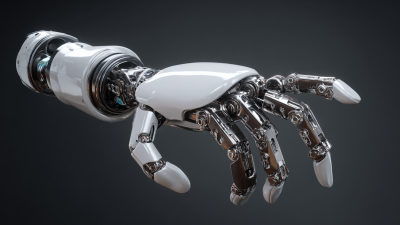

Collaborative robot arms, or cobots, are transforming the landscape of multiple industries by seamlessly working alongside human operators. Unlike traditional industrial robots that require safety cages and extensive programming, cobots are designed to assist in tasks without the need for complex programming or large safety barriers. Their intuitive design allows for easy adaptability in different work environments, enhancing productivity and safety. Manufacturing, logistics, and healthcare are just a few sectors experiencing significant advancements due to cobot integration.

Tips: When considering cobot implementation, it is crucial to assess the specific tasks that could benefit from automation. Begin with low-risk environments to gauge the interaction between human operators and cobots, ensuring a smooth transition. Regular training sessions for employees can maximize the efficiency of cobots and help them integrate into daily operations.

As cobots become more prevalent, industries are reaping the benefits of increased efficiency and reduced labor costs. These robots can handle repetitive tasks, freeing up human workers to focus on more complex and value-added activities. Moreover, with advancements in AI and machine learning, the capabilities of cobots are expanding, allowing them to learn and adapt to new tasks quickly. This evolution not only enhances operational efficiency but also fosters a collaborative workplace culture.

Tips: It’s important to maintain open communication with employees during the implementation of cobots. Seeking their input on the cobots’ functions can lead to better integration and increased acceptance, ensuring that they complement human capabilities rather than replace them.

Top 10 Cobot Robot Arm Applications Revolutionizing Industries

| Application |

Industry |

Benefits |

Automation Level |

| Assembly |

Manufacturing |

Increased precision, reduced labor costs |

High |

| Packaging |

Food & Beverage |

Faster throughput, consistent quality |

Medium |

| Inspection |

Quality Control |

Enhanced accuracy, reduction of human error |

High |

| Machine Tending |

Metalworking |

Increased uptime, reduced labor intensity |

Medium |

| Pick and Place |

E-commerce |

Improved efficiency, minimized loss |

High |

| Welding |

Automotive |

Stronger joints, high repeatability |

High |

| Testing |

Electronics |

Faster results, better error detection |

Medium |

| Repetitive Tasks |

Pharmaceuticals |

Reduced fatigue, higher productivity |

High |

| Material Handling |

Warehousing |

Enhanced safety, efficient logistics |

Medium |

| Painting |

Aerospace |

Uniform application, reduced waste |

High |

Key Industries Benefiting from Cobot Robot Arm Integration

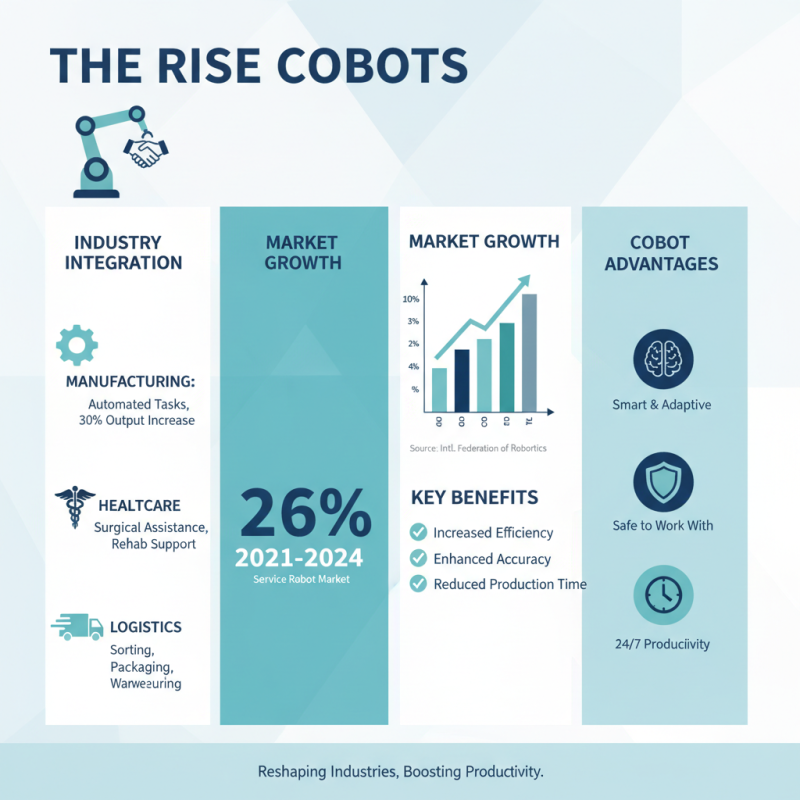

Cobot robot arms are increasingly becoming integral to various industries, reshaping operational efficiency and productivity. Key sectors benefiting from this integration include manufacturing, healthcare, and logistics. According to a report by the International Federation of Robotics, the service robot market is projected to grow at a CAGR of 26% from 2021 to 2024, highlighting the expansive role of collaborative robots. In manufacturing, cobots automate repetitive tasks, enhancing accuracy and significantly reducing production time, as companies report increases in output by up to 30%.

In healthcare, cobot arms assist in surgical procedures, allowing for greater precision and minimal invasiveness. A study from the Journal of Robotic Surgery indicates that robotic-assisted surgeries can reduce recovery times by 20-50%. Additionally, in logistics, cobots streamline warehousing operations, with the McKinsey Global Institute estimating a potential 26% increase in productivity through automation in this sector.

**Tip:** When considering cobot integration, focus on identifying specific tasks that can be automated to maximize ROI. Collaborating with cobots allows human workers to concentrate on more complex tasks, ultimately leading to a more efficient workflow.

Top 10 Innovative Applications of Cobot Robot Arms

Collaborative robots, or cobots, are rapidly transforming industries by enhancing productivity and efficiency. The latest industry reports indicate that the global cobot market is expected to reach $12.3 billion by 2025, growing at a CAGR of 34.5%. This surge is largely driven by innovative applications across sectors ranging from manufacturing to healthcare.

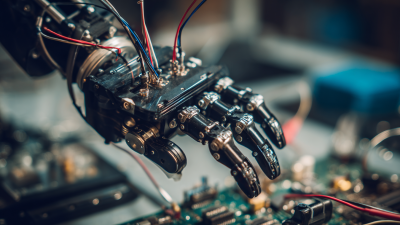

For instance, in manufacturing, cobots are employed for tasks like assembly and quality inspection, allowing human workers to focus on more complex processes. In healthcare, they assist in surgical procedures and patient care, reducing the workload on medical professionals while increasing precision.

Tips: When integrating cobots into your workplace, ensure that they're designed to work alongside human workers safely and effectively. This involves not just choosing the right model for your specific needs but also investing in proper training for your staff. Understanding the strengths and limitations of cobots will facilitate a smoother transition and maximize productivity gains.

Moreover, the food and beverage industry has also benefitted significantly from cobot technology. Recent reports highlight that cobots are increasingly being utilized for packaging, palletizing, and even cooking in some innovative applications. These robots not only streamline processes but also help in maintaining consistent quality and hygiene standards, crucial in today's market. As industries continue to adopt these technologies, the focus on collaboration between humans and robots will shape the future of work significantly.

Tips: Keep an eye on the latest trends and developments in cobot technology. Networking with other businesses that have successfully integrated cobots can provide valuable insights and lessons learned.

Future Trends in Cobot Robotics and Industry Transformation

The landscape of cobot robotics is evolving rapidly, driving transformative changes across various industries. As businesses increasingly adopt collaborative robots, we see a clear trend toward enhanced flexibility and adaptability in manufacturing processes. Cobot arms are designed to work alongside human operators, allowing for seamless collaboration and improved productivity. This shift not only streamlines workflows but also enhances safety, as these robots can take on tedious or hazardous tasks, leaving humans to focus on more complex responsibilities.

Future trends indicate that advancements in artificial intelligence and machine learning will further empower cobots, enabling them to learn from their interactions and optimize their functions over time. This capability will lead to more autonomous operations, where cobots can self-adjust based on real-time data, significantly reducing downtime and increasing operational efficiency. Moreover, as industries continue to embrace Industry 4.0 principles, the integration of cobots with IoT devices will pave the way for smarter, more connected manufacturing environments, transforming traditional labor models and pushing the boundaries of innovation.

Top 10 Cobot Robot Arm Applications Revolutionizing Industries

Challenges and Solutions in Implementing Cobot Technology

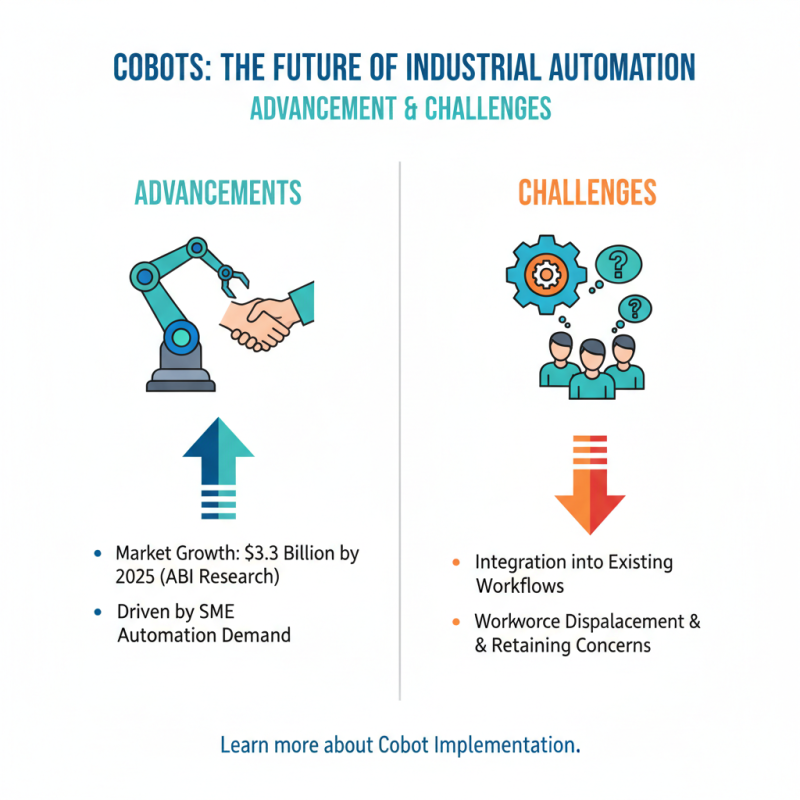

The implementation of collaborative robot (cobot) technology in various industries has brought about significant advancements, yet it is not without its challenges. According to a report by ABI Research, the global cobot market is projected to reach $3.3 billion by 2025, driven by increasing demand for automation in small and medium enterprises. However, many organizations struggle with integrating cobots into existing workflows due to concerns over workforce displacement and the need for employee retraining.

Moreover, ensuring safety and efficiency while collaborating with human workers presents another hurdle. The International Federation of Robotics (IFR) highlights that more than 60% of companies cite safety concerns as a barrier to adopting cobots. To address these issues, organizations can invest in comprehensive training programs that enhance employee skills and foster a culture of collaboration. Additionally, employing advanced safety measures, such as sensors and vision systems, can mitigate risks and enhance operational synergy. By actively tackling these challenges, industries can harness the full potential of cobot technology, paving the way for a more productive and innovative future.

+91-97254 16844

+91-97254 16844