Why Are Cobot Universal Robots Revolutionizing the Future of Automation

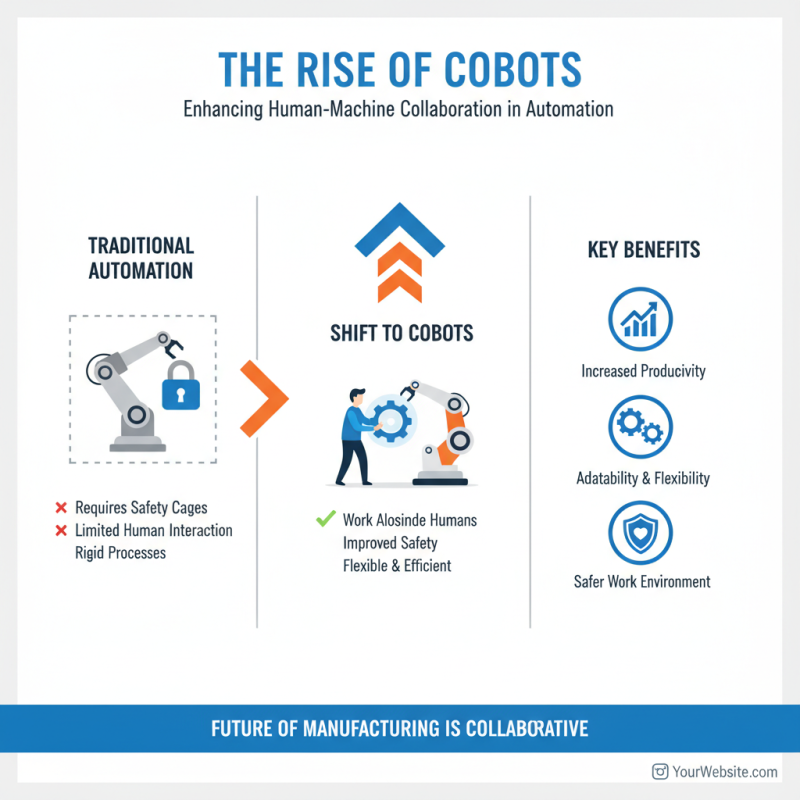

The rise of cobot universal robots marks a significant turning point in the automation landscape, profoundly transforming industries by enhancing efficiency and productivity. Unlike traditional industrial robots, cobots are designed to work alongside humans, supporting a collaborative workspace that maximizes the strengths of both machines and human operators. This synergy opens up new possibilities for automation, allowing businesses to adapt more readily to changing demands and workflows without the need for extensive reconfiguration.

Cobot universal robots are poised to revolutionize not only manufacturing but also logistics, healthcare, and various service sectors. Their versatility and ease of programming empower organizations to implement automation solutions quickly and effectively. Additionally, by integrating intelligent features such as advanced sensors and AI capabilities, cobots can perform complex tasks while ensuring safety in human-robot interactions. As industries navigate the challenges of modernization, the implementation of cobot universal robots holds the key to unlocking significant advancements in operational efficiency and employee satisfaction.

The Rise of Collaborative Robots (Cobots) in Industrial Automation

Collaborative robots, commonly known as cobots, are transforming the landscape of industrial automation by integrating seamlessly into workplace environments alongside human operators. According to a report by Research and Markets, the global collaborative robots market is projected to reach $10.1 billion by 2026, growing at a staggering CAGR of 40.5% from 2021. This rapid growth can be attributed to several factors, including the rising need for greater efficiency, flexibility, and safety in manufacturing processes. Unlike traditional industrial robots, which are often confined to cages for safety reasons, cobots are designed to work in close proximity to humans, allowing for a more versatile and adaptive approach to automation.

The adoption of cobots is driven by their ability to perform repetitive tasks while freeing human workers to focus on more complex and cognitive responsibilities. A study conducted by the International Federation of Robotics found that by 2022, more than 20% of all industrial robots sold will be collaborative robots, underscoring their increasing relevance in various sectors, including automotive, electronics, and consumer goods. Furthermore, cobots can significantly reduce the time required for operational training and implementation. These machines can be easily programmed through intuitive interfaces, allowing companies to leverage automation quickly, thus enhancing productivity and ultimately impacting the bottom line positively.

As businesses strive to remain competitive in an ever-evolving market, the rise of cobots signals a promising shift towards a more integrated and human-centric industrial automation future.

Key Features of Universal Robots Driving Automation Efficiency

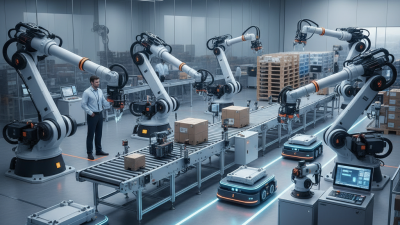

Universal robots, or cobots, are transforming the landscape of automation through their remarkable versatility and ease of integration. One of the key features driving their efficiency is their collaborative design, which allows them to work alongside human operators safely.

This human-robot collaboration minimizes downtime and maximizes productivity as these robots can be programmed to handle repetitive tasks, enabling human workers to focus on more complex activities. Their innate ability to learn from human input and adjust their operation in real time further enhances their adaptability in various work environments.

Another significant feature contributing to automation efficiency is their user-friendly programming interface. Even individuals with minimal technical expertise can set up and operate these robots, reducing the barrier to entry for companies looking to automate processes. This accessibility accelerates deployment and makes it feasible for small and medium enterprises to harness the benefits of automation.

Moreover, the compact design of cobots allows them to be implemented in tight spaces, facilitating automation in diverse settings from manufacturing floors to laboratories without the need for extensive infrastructural changes.

Market Trends: Cobots Impact on Global Automation Industry Growth

The rise of collaborative robots, or cobots, is significantly influencing the global automation industry. As traditional automation often requires extensive safety measures and physical enclosures, cobots are designed to work alongside human operators, enhancing productivity while ensuring a safer workplace. This shift towards integrating human and machine capabilities is driven by the need for flexibility and efficiency in production processes. Organizations are increasingly adopting cobots to meet varying demand levels without the need for complete system overhauls.

Market trends indicate that the adoption of cobots is expanding across various sectors including manufacturing, logistics, and healthcare. With the ability to perform tasks such as assembly, packaging, and material handling, cobots are not only improving operational efficiency but also reducing labor costs and eliminating repetitive strain injuries among workers. This versatility in application is propelling the growth of the global automation industry, as more businesses recognize the financial and operational benefits of incorporating collaborative robots into their workflows. The increasing emphasis on automation in response to labor shortages and the push for higher productivity rates underscores the pivotal role cobots are set to play in shaping the future landscape of work.

Case Studies: Successful Integration of Cobots in Manufacturing

The integration of collaborative robots, or cobots, in manufacturing has proven to be transformative for many industries. Case studies highlight significant successes, particularly in automotive and electronics sectors. For instance, a leading automotive manufacturer reported a 30% increase in production efficiency after incorporating cobots into their assembly lines. These robots work alongside human workers, enhancing productivity without replacing the workforce. According to a recent industry report from the International Federation of Robotics, the cobot market is set to grow at a compound annual growth rate (CAGR) of 44% through 2026, reflecting their increasing acceptance in various manufacturing settings.

Tips for effective cobot integration include assessing workflow and identifying repetitive tasks that benefit from automation. Collaborating with your team to understand their needs and apprehensions regarding new technology is essential to smooth the transition. Additionally, adequate training on operational protocols will maximize the potential of cobots, ensuring safety and efficiency in the workplace.

In a notable case, a global electronics manufacturer successfully integrated cobots in their production line, resulting in a 50% reduction in processing time for small components. This efficiency gain allowed the company to respond more swiftly to market demands, illustrating cobots' capability to enhance not just productivity but also flexibility in manufacturing operations. By adopting a strategic approach to cobot deployment, companies can realize substantial benefits, driving forward the future of automation.

Impact of Cobots on Manufacturing Efficiency

Future Prospects: The Role of AI in Enhancing Cobot Capabilities

The integration of artificial intelligence (AI) into collaborative robots, or cobots, is set to enhance their functionalities significantly, pushing the boundaries of automation in various industries. According to a report by MarketsandMarkets, the global cobot market is projected to grow from USD 1.7 billion in 2021 to USD 9.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 40.1%. This explosive growth can be largely attributed to the advancements in AI technologies, which enable cobots to interact more intelligently and efficiently with their human counterparts.

AI contributes to cobots in several meaningful ways, such as improving perception through advanced computer vision, facilitating adaptive learning processes, and enabling real-time data analysis. For instance, a study by PwC indicates that 72% of companies believe they will benefit from using AI alongside automation technologies to drive productivity improvements. By equipping cobots with machine learning algorithms, they can learn from their environment and user interactions, thus becoming more versatile in handling tasks from assembly to packaging. This capability not only streamlines operations but also reduces the need for extensive reprogramming, allowing for quicker adjustments in dynamic manufacturing landscapes.

The enhancement of cobots through AI is not simply about improving performance; it represents a fundamental shift in the automation paradigm. By making cobots more autonomous and capable of performing complex tasks with minimal human intervention, businesses can achieve higher efficiency and flexibility. The integration of AI-driven capabilities will ultimately redefine roles within the workforce, allowing human workers to focus on higher-value activities while leaving repetitive and mundane tasks to their automated counterparts. This evolution in collaborative automation illustrates the profound potential that AI has in reshaping industries and fostering innovation in the workplace.

Why Are Cobot Universal Robots Revolutionizing the Future of Automation - Future Prospects: The Role of AI in Enhancing Cobot Capabilities

| Dimension |

Description |

Current Value |

Future Potential |

| Integration Level |

Ease of integrating cobots with existing systems |

High |

Very High (improved AI will enhance compatibility) |

| AI Utilization |

Degree of AI application in cobot functions |

Moderate |

High (advanced analytics and machine learning) |

| Cost Effectiveness |

Operational costs versus traditional automation |

Low |

Very Low (AI reduces downtime and labor costs) |

| Task Flexibility |

Ability to adapt to different tasks on the fly |

Moderate |

High (AI can learn and optimize task execution) |

| Worker Collaboration |

Effectiveness of human-cobot interaction |

High |

Very High (with smart AI interfaces) |

+91-97254 16844

+91-97254 16844