What are Collaborative Robots and How Do They Work?

Collaborative robots, often referred to as cobots, are revolutionizing the industrial landscape. According to a report by MarketsandMarkets, the global collaborative robot market is expected to reach $12.3 billion by 2025, growing at a CAGR of 40.5%. This rapid growth highlights the increasing demand for automation in manufacturing and assembly processes.

These robots are designed to work alongside human operators, enhancing productivity and safety. Unlike traditional industrial robots, collaborative robots are equipped with advanced sensors and machine learning capabilities. They can detect human presence and adjust their operations accordingly. However, the integration of cobots into existing workflows is not without challenges. Industries must consider employee training and system compatibility.

Despite their potential, the deployment of collaborative robots can raise concerns about job displacement. It is crucial for companies to address these issues mindfully. While cobots can improve efficiency, they also require a strategic approach to ensure a harmonious human-robot collaboration. Balancing the benefits of automation with the needs of the workforce remains a fundamental task for the industry.

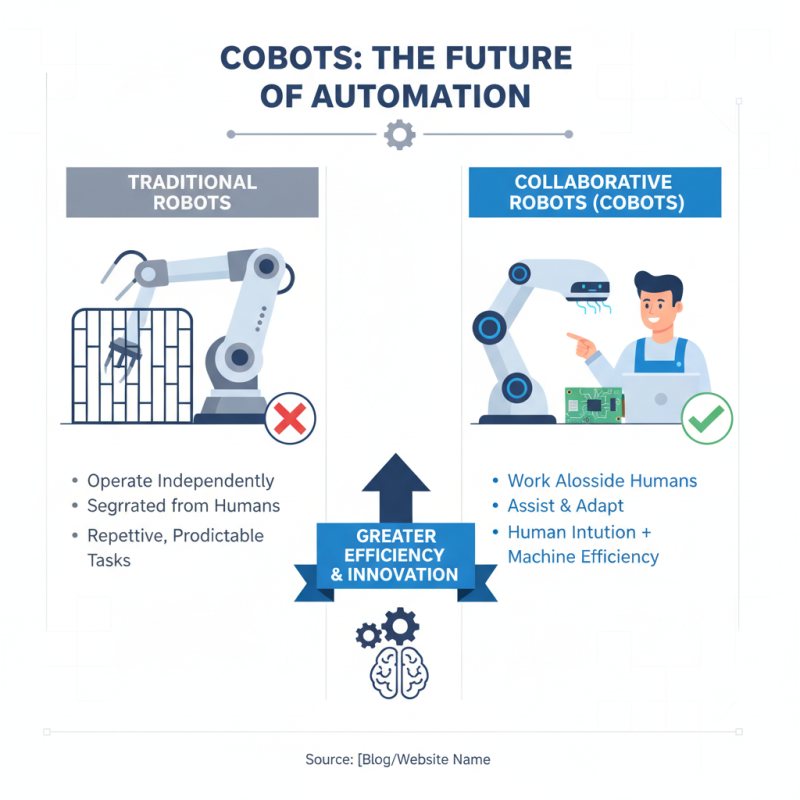

Understanding the Definition of Collaborative Robots (Cobots)

Collaborative robots, often known as cobots, are revolutionizing the way we think about automation. Unlike traditional robots, which operate independently, cobots work alongside humans. They are designed to assist in tasks that require human intuition and adaptability. This combination of human and machine efforts can lead to greater efficiency in various industries.

The definition of a collaborative robot is not just about its ability to work side by side with people. It emphasizes safety and ease of use. Cobots are equipped with sensors and advanced algorithms. This allows them to detect human presence and adjust their movements accordingly. However, there are still challenges. For instance, the programming of cobots can sometimes be complex. Also, optimal collaboration still requires ongoing training of human workers.

Additionally, cobots can automate repetitive tasks. This might enhance productivity but can also create concerns about job displacement. The integration of cobots into the workforce raises questions about the balance between human jobs and automation. Understanding how cobots work is crucial for addressing these issues effectively. How can we ensure the safe and ethical use of this technology in our workplaces?

Key Features of Collaborative Robots: Safety and Versatility

Collaborative robots, or cobots, are transforming the automation landscape. They are designed to work alongside humans. This setup enhances safety and productivity. One key feature of cobots is their built-in safety measures. They can detect nearby human presence and slow down or stop if someone gets too close. This reduces the risk of workplace accidents.

Versatility is another essential aspect of collaborative robots. They can adapt to different tasks quickly, from assembly to packaging. Their user-friendly interfaces allow operators to program them easily. However, their flexibility can sometimes lead to over-automation. Not all tasks are suitable for robots. Some require human intuition and decision-making.

In the quest for efficiency, a balance is necessary. Cobots excel in repetitive tasks. Yet, complex jobs still thrive under human control. The future may incorporate more advanced cobots with better capabilities. Still, it's crucial to assess which tasks they’re suited for. Growing too reliant on them can lead to unforeseen challenges.

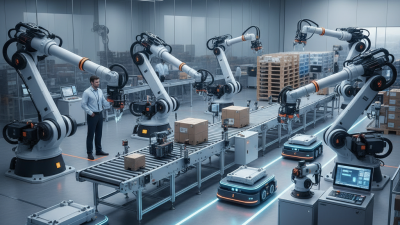

Types of Collaborative Robots and Their Applications Across Industries

Collaborative robots, often known as cobots, are designed to work alongside humans. Their applications span various industries, including manufacturing, healthcare, and logistics. According to recent industry reports, the global collaborative robot market is projected to reach $12 billion by 2026, growing at a compound annual growth rate of over 40%. This remarkable growth reflects the increasing reliance on automation in various sectors.

In manufacturing, cobots assist in tasks such as assembly and packaging. They enhance productivity while ensuring worker safety. In healthcare, these robots support surgical procedures and assist with patient care. However, the lack of understanding of cobot capabilities causes hesitance among employees. There's still a learning curve in integrating this technology. Some workers worry that collaboration might lead to job redundancy, which creates an atmosphere of uncertainty.

Logistics also benefits from cobots. They help in sorting and packing items efficiently. With companies increasingly focusing on cost reduction, cobots provide a solution. Nonetheless, organizations must address the complexity of task allocation between humans and machines. Proper training and clear communication are essential for successful integration. The balance of human and robotic collaboration remains a challenge, necessitating ongoing reflection and adaptation.

How Collaborative Robots Integrate with Human Workforce

Collaborative robots, or cobots, are designed to work alongside human operators. They are not here to replace workers. Instead, they aim to enhance productivity. These machines can handle repetitive tasks, which frees up humans for more complex work. This synergy can lead to greater job satisfaction and creativity among employees.

Integration is key for cobots. They are equipped with sensors that allow for safe interaction with humans. For example, a cobot might assist in assembling parts while a worker manages quality control. This setup enhances workflow efficiency. However, challenges remain. There may be a learning curve for workers unfamiliar with robotics. Sometimes, the coordination between human and robot can be awkward. Ensuring both parties communicate effectively is essential.

Training is pivotal in this integration process. Workers need to understand how to operate cobots safely. Misunderstandings could lead to accidents or inefficient workflows. It is vital for companies to foster a culture that embraces technology while valuing human input. Only then can the full potential of collaborative robots be realized.

The Future of Collaborative Robots in Automation and Industry 4.0

The rise of Collaborative Robots (cobots) marks a significant shift in automation and Industry 4.0. By 2025, the global cobot market is expected to reach $12 billion, according to a recent market report. Cobots are designed to work alongside humans, enhancing productivity in various industries. They can work safely in close proximity to workers, creating a dynamic and integrated manufacturing environment.

Despite their advantages, the adoption of cobots presents challenges. Businesses often face difficulty in integration with existing systems. Cobots require careful programming and setup. This may lead to hesitancy among companies reluctant to invest time and resources upfront. According to a study, 40% of manufacturers express concerns about the complexity of integrating cobots into daily operations.

However, the future remains promising. Automation is predicted to increase by 30% in the coming years, driven by cobot technology. As companies seek efficiency, the potential for cobots to evolve and adapt to various tasks will lead to greater acceptance and usage. Many organizations now view cobots as essential tools in maximizing productivity and ensuring workforce safety. This transformative change is merely the beginning of their journey in the industrial landscape.

+91-97254 16844

+91-97254 16844